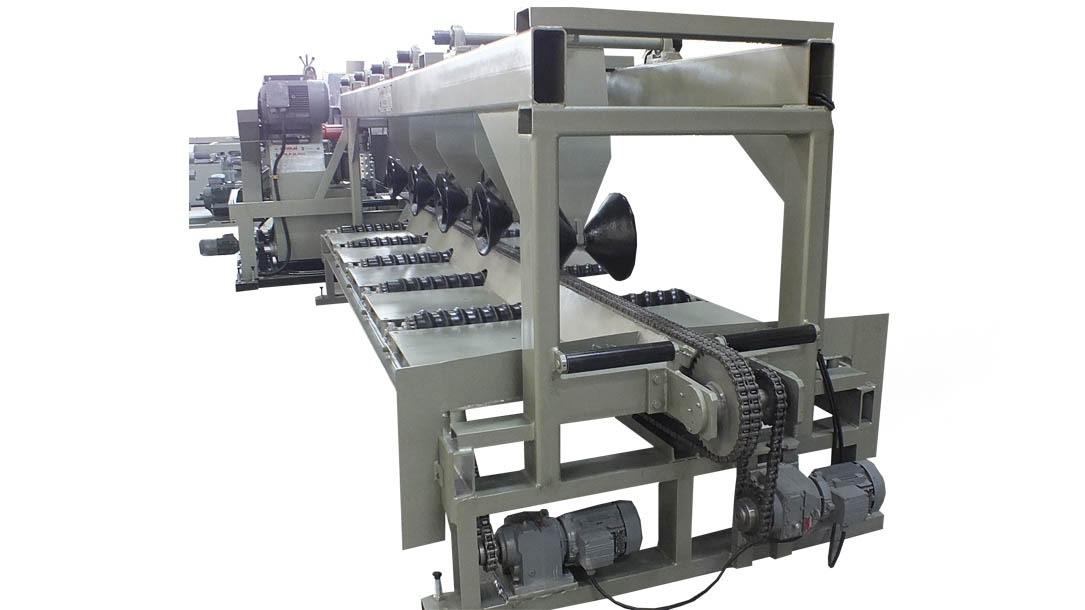

SG 100 MSM GENERAL FEATURES

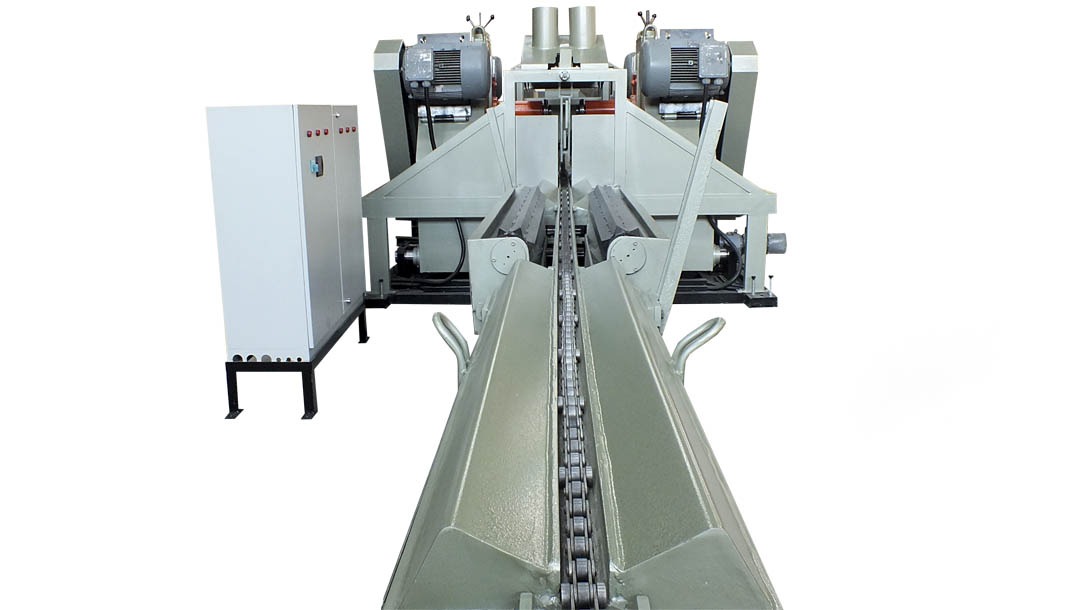

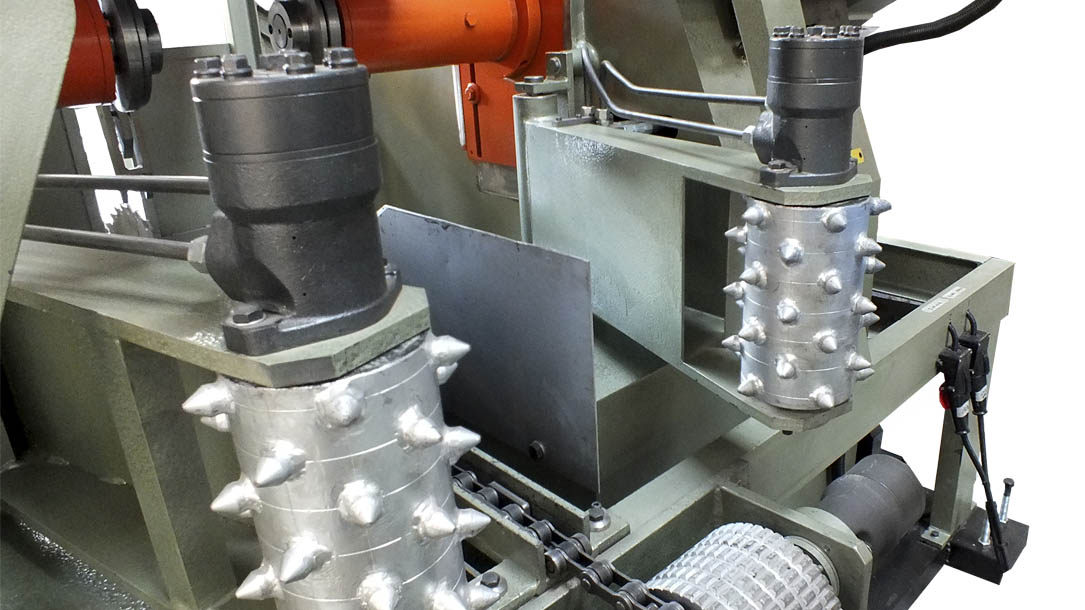

The body of the machine is of steel construction. There are 4 moving conveyor cylinders and 2 pressure cylinders on the machine and they are redirector controlled. Saw sizes are fixed but flanges can be replaces when different sizes are going to be cut. Movement of the upper printing rollers, according to the thickness of the product is made with manual. A concrete hole must be designed for the sawdust coming out of the machine. Direction set squares are used for materials with one clean side. Inverter is controlled with an attractive rate and pressure rollers. Speed is 0+40 m/m.

SG 100 MSM TECHNICAL SIZE

- Length-Width-Height : 1900 – 1600 – 1350 mm

- Saw motor power : 45KW 3000 D/D

- Redirector motor : 2,2 KW 171 D/D outlet

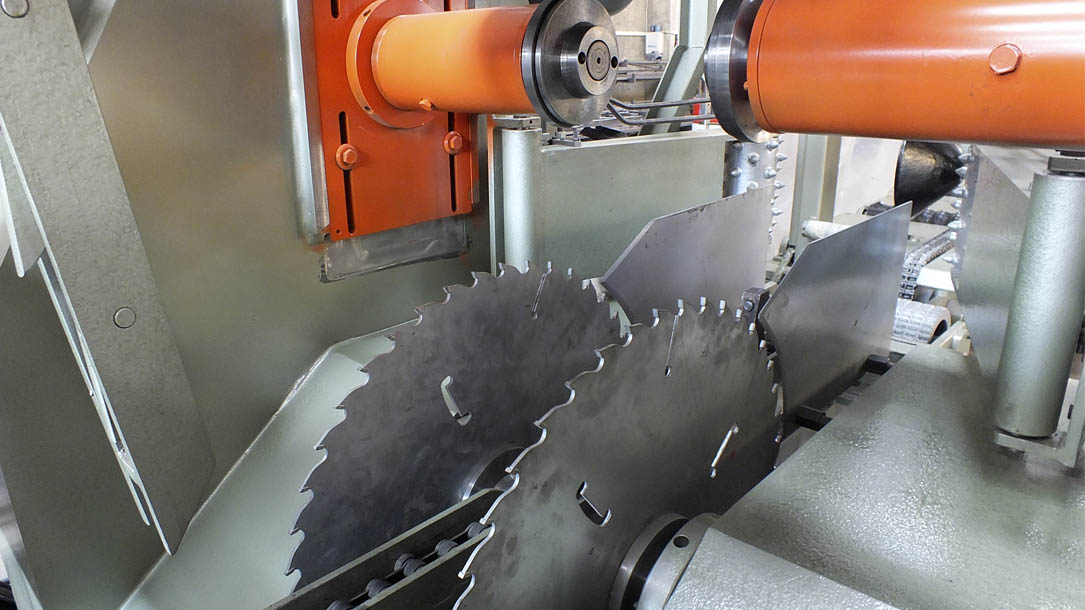

- Saw diameter : Max.: Ø 350 mm

- Saw hole diameter : Ø 70 mm

- Cutting width : Max. : 800 mm

- Cutting thickness : Max. : 100 mm

- Number of saws : Maximum quantity: 8

- Cutting speed : Max : 40 m/min

- Saw period : 3000 D/D

- Approximate weight : 1350 kg

- Color : White and ocean blue

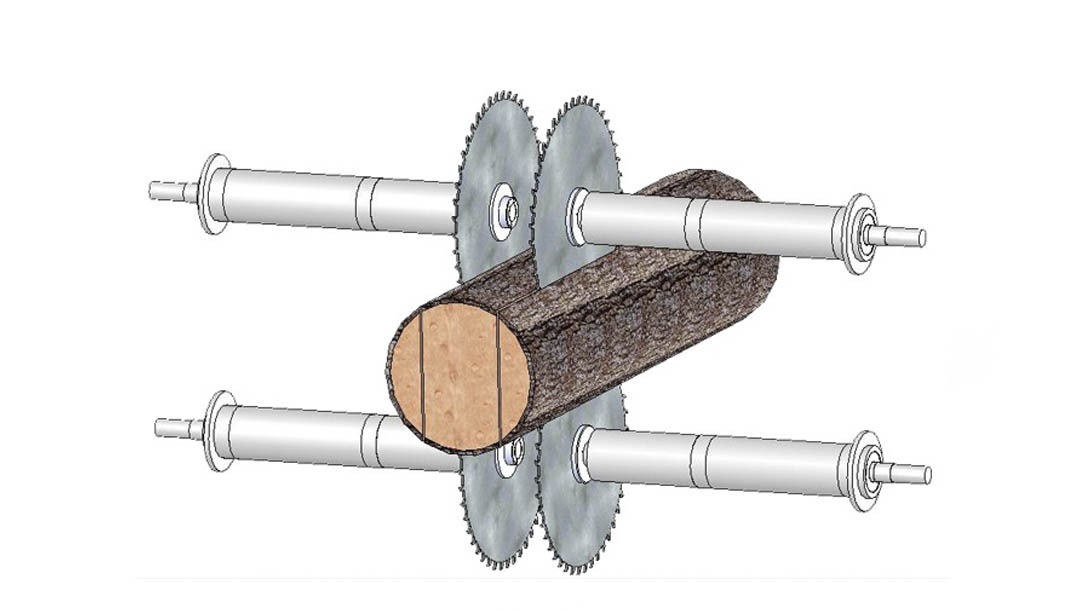

SG 100 MSM WORKING PRINCIPLE

SG 100 MSM Mechanical System Multi-Slicer, max: 100 mm height for the timber group of companies working ranges of products are manufactured in different sizes. The inside of the machine is designed to be 810 mm. Saw shaft with feather key length of 650 mm. Circular saws with diamond cutting process is provided. Saw shafts fixed. 300mm saw blade can be installed. Attractive gear motor with rollers is moving. Movement of the upper pressure roller adjustment process is carried out manually. 1 up to 40 m long used the machine speed rapidity fully engaged in the cutting process. For example, 100 mm high, 6000mm long, 400mm wide makes 1 m3 of timber is assumed to be smooth. In 1 hour and 40 m3 tree cutting machine can cut. The calculation may vary depending on the dimensions.